In Malaysia's vibrant food processing industry, maintaining impeccable cleanliness is not just a regulatory obligation but a fundamental necessity for safeguarding public health and ensuring the quality of food products. The use of chemical agents to clean equipment and surfaces—such as floors, countertops, walls and even ceilings—is pivotal in this endeavor. This article explores the significance of cleanliness in Malaysian food processing plants from the standpoint of chemical cleaning, highlighting key considerations for upholding high standards in this tropical part of the world.

Regulatory Compliance in Malaysia

Adherence to cleanliness standards is mandated by Malaysian laws and regulations. The Food Act 1983 and the Peraturan-Peraturan Makanan (Food Regulations) 1985, enforced by the Ministry of Health Malaysia, set stringent guidelines for sanitary conditions in food processing facilities. These regulations are designed to prevent food contamination and ensure that food products are safe for consumption. Non-compliance can result in severe penalties, including fines, revocation of licenses, or even closure of facilities. Therefore, utilizing appropriate chemical cleaning agents is essential for meeting these regulatory requirements and avoiding legal repercussions.

Preventing Contamination in a Tropical Climate

Malaysia's tropical climate presents unique challenges for the food processing industry. High temperatures and humidity levels create an ideal environment for the growth of microorganisms such as bacteria, fungi, and mold. Chemical sanitizers and disinfectants are effective tools for eliminating these pathogens from surfaces and equipment. Regular and thorough cleaning minimizes the risk of microbial contamination, which can lead to foodborne illnesses if not properly managed.

Cross-contamination is another significant concern. In facilities where multiple food products are processed, allergens and pathogens can easily transfer from one product to another if proper cleaning protocols are not followed. Implementing meticulous chemical cleaning routines ensures that all traces of previous products are removed, protecting consumers with food allergies and maintaining overall food safety.

Health and Safety Considerations

Protecting consumer health is the primary objective of cleanliness in food processing. Foodborne illnesses not only endanger public health but can also damage the reputation of a food manufacturer’s products in both domestic and international markets. The importance of preventing food poisoning through the consumption of contaminated food cannot be overstated, especially when it involves potential loss of life. By employing effective chemical cleaning practices, food manufacturers can significantly reduce the risk of food contamination incidents.

Employee safety is equally important. Handling chemical cleaning agents in a safe but effective manner requires proper knowledge and precautions. Workers must be equipped with appropriate Personal Protective Equipment (PPE), such as gloves, goggles, and protective clothing, to prevent unwanted chemical exposure and injury. Regular training on the safe handling and usage of cleaning chemicals is essential to maintain a safe working environment and comply with the Occupational Safety and Health Act 1994.

Aside from the proper handling of chemicals and having appropriate PPE to prevent injury, it is important that the chemicals themselves do not pose long term hazards to the user. In Europe, the restriction of chemicals whose components are deemed detrimental to health and/or the environment at certain concentrations is regulated by a directive known as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals). Proposition 65, which is a directive issued by the state of California in the US, maintains a list of chemicals known to cause cancer or reproductive issues. Although chemical manufacturers are not required to adhere to REACH and Proposition 65 for the supply of chemicals within Malaysia, many Malaysian companies require that the chemicals they use do not cause harm, as defined by the two directives.

Halal-Compliant, Effective Cleaning Chemicals

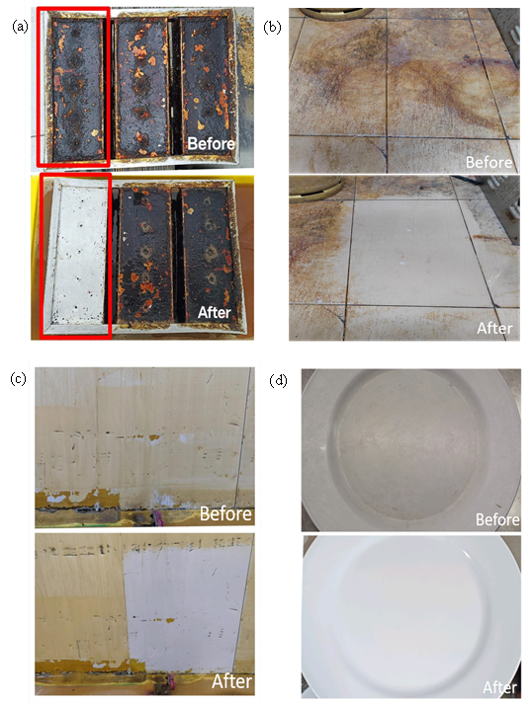

Different surfaces and equipment may require specific chemicals based on their material composition and the type of contaminants present. Establishing a comprehensive cleaning schedule, with detailed protocols outlining the methods and frequency of cleaning, helps maintain consistency and thoroughness. Documentation of cleaning activities is also essential for audits and inspections, demonstrating compliance and due diligence. However, having an effective cleaning process in place is not enough. In Malaysia, where halal certification is crucial for many food products, companies must ensure that the chemicals used are compliant with halal standards set by the Department of Islamic Development Malaysia (JAKIM). This includes verifying that cleaning agents do not contain any non-halal ingredients and are used in a manner that aligns with halal practices. Figure 1 illustrates the efficacy of our cleaning products in achieving optimal cleaning results, demonstrating significant improvements in cleanliness across various surfaces.

A Good Cleanliness Program Provides Benefits

Regular chemical cleaning not only ensures hygiene but also contributes to the maintenance and longevity of equipment. In Malaysia's humid environment, residue build-up can accelerate equipment corrosion and promote the growth of biofilms, which are difficult to remove and can harbor harmful microorganisms. By keeping equipment clean, companies can extend the lifespan of their machinery, reduce downtime, and avoid costly repairs or replacements.

Investing in proper cleanliness practices also offers significant financial benefits. Food contamination incidents can lead to product recalls, legal liabilities, and loss of consumer trust—outcomes that can be particularly damaging in Malaysia's competitive food industry. By proactively maintaining cleanliness, companies can avoid these financial pitfalls. Moreover, consistent product quality enhances a company’s reputation as a reliable food exporter, opening doors to international markets and boosting sales.

Environmental Considerations

Environmental sustainability is an increasingly important consideration in Malaysia. The government encourages industries to adopt eco-friendly practices, including the use of biodegradable and non-toxic cleaning agents. Proper disposal of chemical waste is regulated under the Environmental Quality Act 1974, which aims to prevent environmental pollution. Companies must ensure that waste management practices comply with these regulations to protect Malaysia's rich biodiversity and natural resources.

Training and Education

The effectiveness of chemical cleaning largely depends on the knowledge and competence of the staff. Training programs ensure that employees understand correct cleaning procedures, proper use of chemicals, and safety protocols. This ensures that a high standard of cleanliness is achieved and maintained in a consistent manner that stands up to rigorous audits and random inspections. Furthermore, the provision of and familiarity with Safety Data Sheets (SDS) for each chemical product used is essential for handling emergencies and preventing accidents.

Technological Advances

Advancements in cleaning technology offer new opportunities for improving cleanliness in Malaysian food processing plants. Automation of cleaning processes, such as Clean-in-Place (CIP) and auto dosing systems, allows for consistent and efficient sanitation of equipment without disassembly. Innovations in chemical formulations provide higher cleaning performance, improve cost effectiveness, and incorporate components that are safe for both humans and the environment. Embracing these technologies can help companies stay competitive and meet international standards.

Conclusions

Maintaining cleanliness in Malaysia's food processing industry through the use of chemical cleaning agents is a multifaceted endeavor that encompasses regulatory compliance, health and safety, operational efficiency, and environmental stewardship. It is an investment that protects consumers, employees, and the company's bottom line. As the industry evolves, embracing best practices in chemical cleaning will remain a cornerstone of producing safe, high-quality food products. This means that industry stakeholders must prioritize sanitation, continually educate their workforce, and stay abreast of technological advancements to uphold the highest standards of food safety - all without exacting a heavy toll on the environment.

Putting such a comprehensive cleaning program in place, with its many demanding requirements, may seem highly daunting. Fortunately, Cosmic Discovery Sdn Bhd has over 30 years of experience and the expertise to provide the best halal-certified chemical cleaning solutions, technical support, and training services to food processing companies, both large and small, from big manufacturing plants to compact shop lots. Contact us today at main@cosmicdiscovery.com.my or call us at +60 3 3291 9388.