In the rapidly industrializing landscape of Malaysia, the importance of proper wastewater treatment cannot be overstated. As factories continue to play a pivotal role in the country's economic growth, the responsible management of industrial effluents has become a critical concern for both environmental preservation and regulatory compliance. This article explores the significance of wastewater treatment in Malaysian factories, and the crucial role that chemicals play in that process.

The Environmental Imperative

The impact of untreated or inadequately treated wastewater on the environment is profound and far-reaching. When industrial effluents are discharged into water bodies without proper treatment, they can cause severe ecological imbalances. These pollutants may include heavy metals, organic compounds, and other toxic substances that can harm aquatic life, contaminate drinking water sources, and disrupt entire ecosystems. In Malaysia, where rivers and coastal areas are not just vital for biodiversity but also for tourism and local livelihoods, protecting these water resources is paramount. The long-term consequences of water pollution can lead to health issues for local communities, loss of biodiversity, and economic repercussions that extend far beyond the immediate vicinity of the pollution source.

Regulatory Landscape in Malaysia

Recognizing the critical need to protect its water resources, Malaysia has implemented stringent regulations governing industrial wastewater discharge. The Environmental Quality Act 1974 and its subsequent amendments set clear standards for effluent quality. The Department of Environment (DOE) actively enforces these regulations, requiring factories to obtain licenses and comply with specific discharge limits for various pollutants.

Malaysia's environmental regulations categorize discharge areas into two standards: Standard A and Standard B. Standard A typically includes water supply catchment areas and any area upstream of any intake point for water supply. The discharge limits for Standard A are more stringent due to the direct impact on water resources used for human consumption. Standard B covers areas other than those designated as Standard A. While still stringent, the discharge limits for Standard B are slightly more relaxed compared to Standard A. Some key parameters and their respective limits for Standard A and B are presented in the table below.

| Parameter | Unit | Standard A | Standard B |

| pH | - | 6.0 - 9.0 | 5.5 - 9.0 |

| Biochemical Oxygen Demand (BOD5) | mg/L | 20 | 50 |

| Chemical Oxygen Demand (COD) | mg/L | 80 | 200 |

| Total Suspended Solids (TSS) | mg/L | 50 | 100 |

| Oil and Grease | mg/L | 1.0 | 10 |

It should be noted that these are general guidelines, and specific industries may have additional parameters to monitor and stricter limits to adhere to, depending on the nature of their operations.

Non-compliance with these regulations can result in hefty fines, license revocations, and even legal action against factory operators. Factories must be acutely aware of their location and the applicable discharge standards, as the consequences of non-compliance can be severe. Therefore, effective wastewater treatment is not just an environmental responsibility but a legal and financial imperative for Malaysian factories.

The Role of Chemicals in Wastewater Treatment

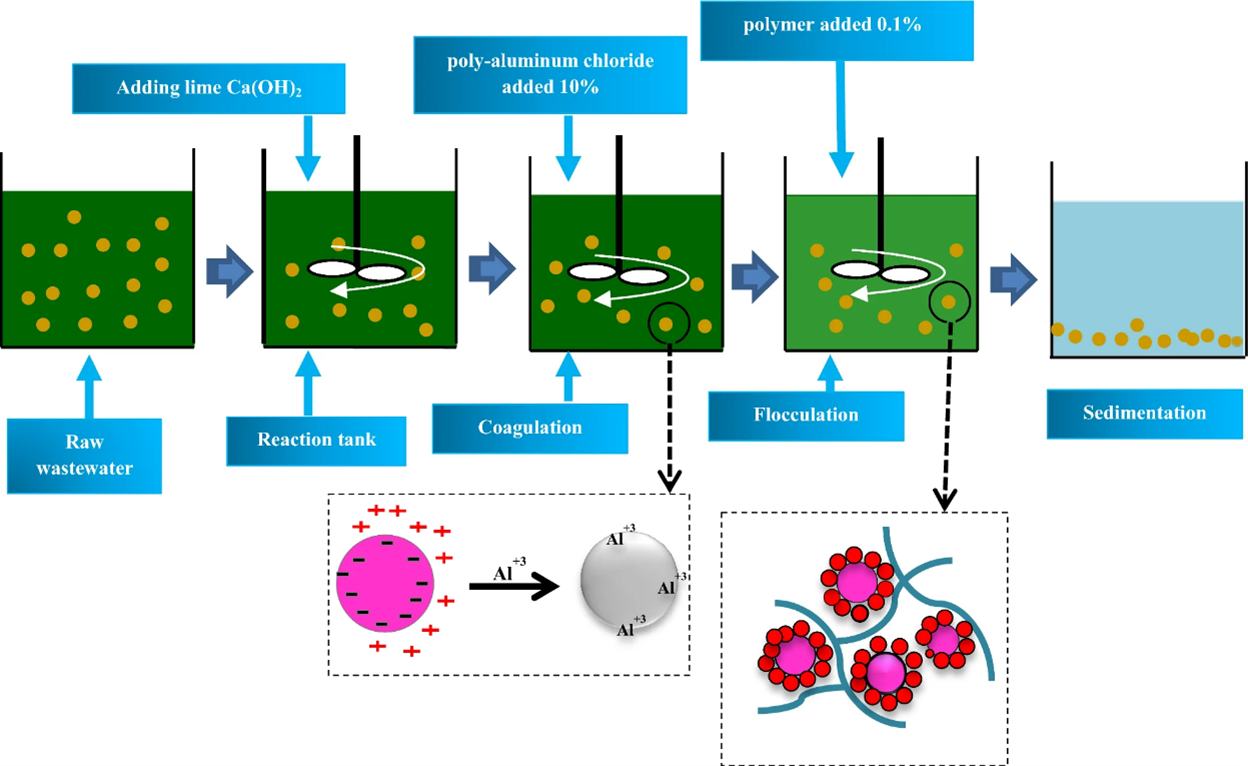

At the heart of effective wastewater treatment lies the crucial process of removing pollutants through chemical treatments. Among these, coagulation and flocculation play pivotal roles in separating contaminants from water.

Coagulation involves adding chemicals (coagulants) that neutralize the electrical charges of particles in the wastewater, causing them to destabilize. This allows the particles to come closer together, forming larger particles called "flocs."

Flocculation follows coagulation and involves gentle mixing to encourage these destabilized particles to collide and form even larger flocs. These larger flocs are then easier to remove through subsequent processes like sedimentation or filtration.

Traditionally, these processes required separate treatment tanks and different chemicals, adding complexity and cost to the wastewater treatment process. However, innovative solutions are changing this landscape.

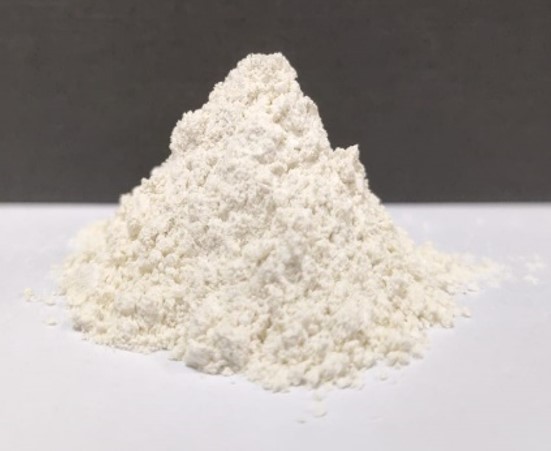

Cosmic Discovery's COS E-FLOC

We at Cosmic Discovery Sdn Bhd strongly believe that wastewater treatment should be simple, efficient, and cost-effective. Our carefully formulated composite flocculant COS E-FLOC streamlines wastewater treatment by combining the coagulation and flocculation process into a single step, thereby eliminating the need for separate treatment tanks and different chemicals for each process. This advanced chemical solution is designed to help industries meet the stringent discharge standards set by the DOE while making the wastewater treatment process convenient and fault-tolerant.

Key benefits of Cosmic Discovery's composite flocculant COS E-FLOC include:

- Simplified Process: By combining coagulation and flocculation, the treatment process becomes more straightforward, reducing the complexity of wastewater treatment systems.

- Cost-Efficiency: The elimination of multiple chemical additions and separate treatment tanks translates to significant cost savings in both capital expenditure and ongoing operational expenses.

- Space Optimization: With a reduced need for multiple treatment tanks, factories can optimize their space usage, a crucial factor in space-constrained industrial settings.

- Improved Efficiency: The single-step process often results in faster treatment times and more consistent results, enhancing overall treatment efficiency.

- Fault-Tolerant: Unlike conventional approaches using polyaluminium chloride for coagulation and a cationic polymer (e.g. PAM) for flocculation, overdosage with COS E-FLOC does not cause the overall wastewater treatment process to fail.

- Easier Compliance: The simplified process and improved efficiency make it easier for factories to consistently meet regulatory standards, reducing the risk of non-compliance penalties.

- Versatility: Cosmic Discovery's composite flocculant is designed to be effective across a wide range of industrial effluents, making it a versatile solution for various manufacturing sectors.

Importantly, we recognize at Cosmic Discovery that each industry faces unique wastewater challenges. Our team collaborates with clients to develop tailored solutions that address specific needs and regulatory requirements. From initial consultation to implementation and ongoing support, we offer comprehensive technical assistance and support to ensure seamless integration of our composite flocculant into your treatment process.

The Path Forward

As Malaysia continues its trajectory of industrial growth, the adoption of advanced wastewater treatment solutions like Cosmic Discovery's COS E-FLOC becomes increasingly crucial. By embracing these innovative technologies, factories can not only ensure compliance with regulatory standards but also contribute significantly to environmental conservation efforts.

The benefits extend beyond mere regulatory compliance. Factories that invest in effective wastewater treatment solutions often find themselves at a competitive advantage. They build stronger relationships with local communities, enhance their corporate image, and position themselves as responsible corporate citizens in an increasingly environmentally conscious market.

In conclusion, the importance of wastewater treatment cannot be overstated. It is a critical step towards ensuring environmental sustainability, regulatory compliance, and long-term business viability. With innovative solutions like COS E-FLOC leading the way, Malaysian industries have the opportunity to set new standards in responsible manufacturing practices.

The CDSB R&D Team